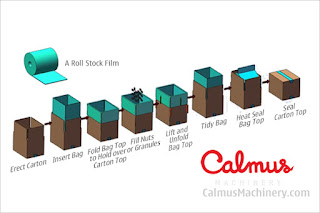

Erect-Line-Fill-Seals Bag in Box Packaging Line. This bag in box forming, filling and sealing line is designed for packaging nuts or granules with liner bags in boxes. Erect cartons and seal bottoms to form boxes, insert and line open-top bags in cartons, fill products, vacuumize and heat-seal bags, seal box top, all automatically.

|

Bag in Box Forming Filling and Sealing Line

for Packaging Nuts or Granules |

|

Procedure of Bag in Box Line

for Packaging Nuts or Granules |

The bag in box forming and packaging line includes a carton erector, a carton lining machine (lining bags in erected cartons by one each), a filling machine, a liner bag sealer, a carton sealer and conveyors. The cartons can be sealed with tape or hot melt glue.

The

carton lining machine inserts a poly bag in a box, open and folds the bag top over the box top, blow air to expand the bag to fit on the internal wall of carton better. The machine reduces labor and material costs, is simple to operate and easy to adjust. High efficiency and labor saving.

The

liner bag sealer takes the folded bag top off the box top, then folds it inwards from sides, vacuumizes the bag (optional), heat-seals the bag top and then folds it in the box.

Specifications:

Applicable cartons: L250-550*W200-400*H150-400mm

Applicable bags (width): 460-840mm

Capacity: max. 180 boxes/hour

|

Carton Liner/Bag Inserter

of Bag in Box Line |

|

Granules Conveyor of Bag in Box Line

|

|

| Bag Sealer of Bag in Box Line |

|

| Carton Top Sealer of Bag in Box Line |